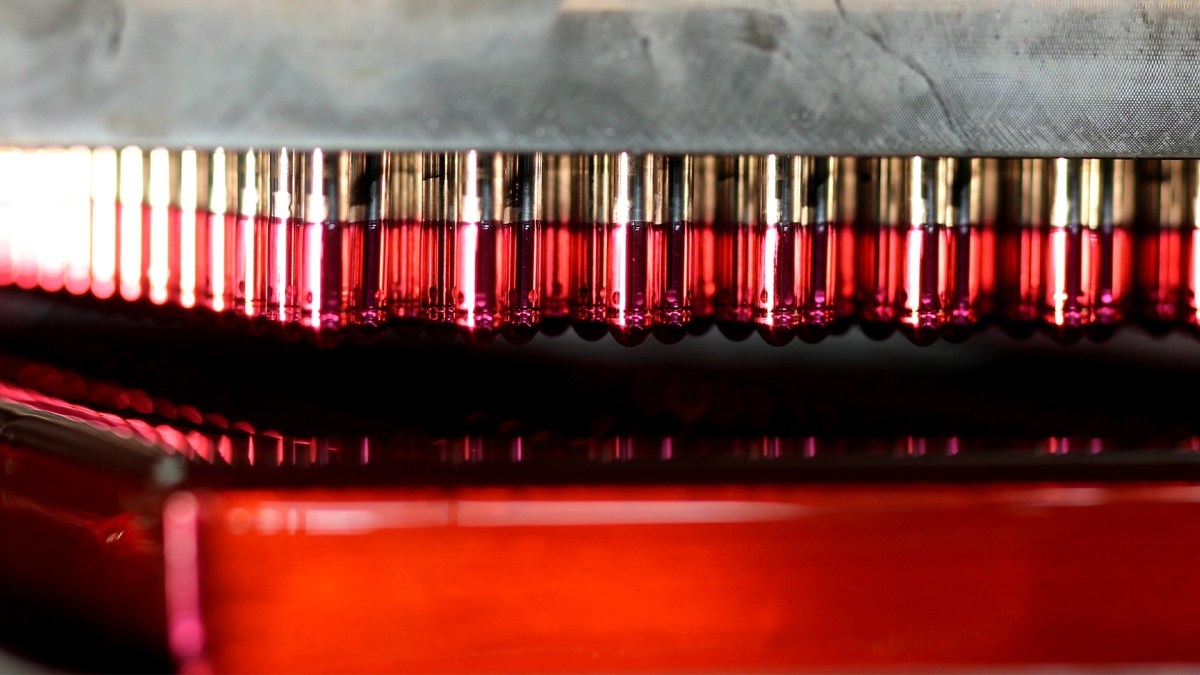

You can trust us

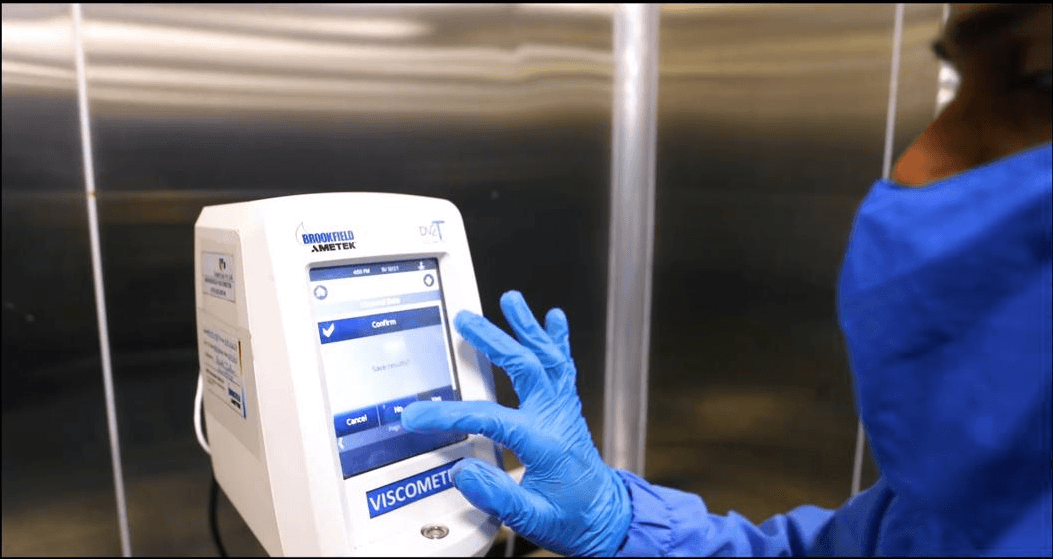

Sanitisation,

Hygiene & Safety

Sanitisation and hygiene are practiced in every aspect of manufacturing of product. Sanitisation and hygiene covers personnel, premises and equipment's.

Each personnel, who is directly or indirectly involved in the manufacturing of the product undergoes medical check up at regular intervals and trained for hygiene practices. Safety training is given to individuals with respect to their work areas and appropriate protective apparels are provided.